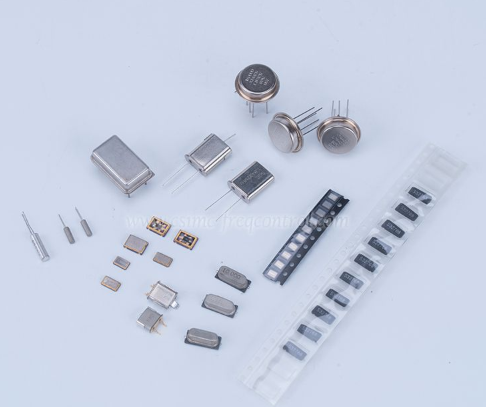

Here is Finished Crystal China Wholesaler talking about Wafer.

If you have any idea about Finished Crystal, welcome to contact us and discuss.

To be simple, firstly, it is extracted from ordinary silicon (silicon) sand, and a series of measures such as dissolution, purification and distillation are utilized to make a single crystal rod. After the single crystal silicon rod is polished and chopped, single crystal silicon is obtained. Silicon) wafer, also called a wafer.

After the silica ore (quartz sand) is mixed with coke, it is heated and reduced by an electric arc furnace to make crude silicon (purity of 98 percent, metallurgical grade).

Due to the precision of electronic elements, silicon wafers have to have a comparatively large purity (99.999999999%). Otherwise, there'll be defects.

The wafer fabrication factory then melts the polysilicon (silicon) by Chalcola method and then incorporates a little crystal of silicon (silicon) crystals into the solution, then gradually pulls it out to form a cylindrical shape. The diameter of the ingot is the width of the wafer.

After being sliced, ground, and polished, the silicon (silicon) ingot becomes the silicon (silicon) wafer, the basic material of the integrated circuit factory. This is actually the"wafer".

The wafer is processed by multiple photomasks, each of which includes sensitizer coating, exposure, development, etching, infiltration, implantation, etching or evaporation, etc., to copy the circuit on the photomask to Over the layered wafer, an IC wafer with multiple layers of components and lines is fabricated, then passed into a test, cutting, and packaging mill in the latter stage to form a physical integrated circuit product. Generally speaking, big wafers (12 吋) are used to make ICs with lower levels of technology such as memory, while small wafers (6 吋) are utilized to make ICs with higher levels of technology like analog ICs. Then you will find.

In the wafer to be processed into a commodity demands a professional and detailed division of labor.

Want to know more about the price of Wafer, you can consult Finished Crystal Wholesaler.

Looking forward to receiving your inquiry.

Copyright © Hangzhou Freqcontrol

Electronic Technology Ltd.

All Rights Reserved | Sitemap |

Powered by