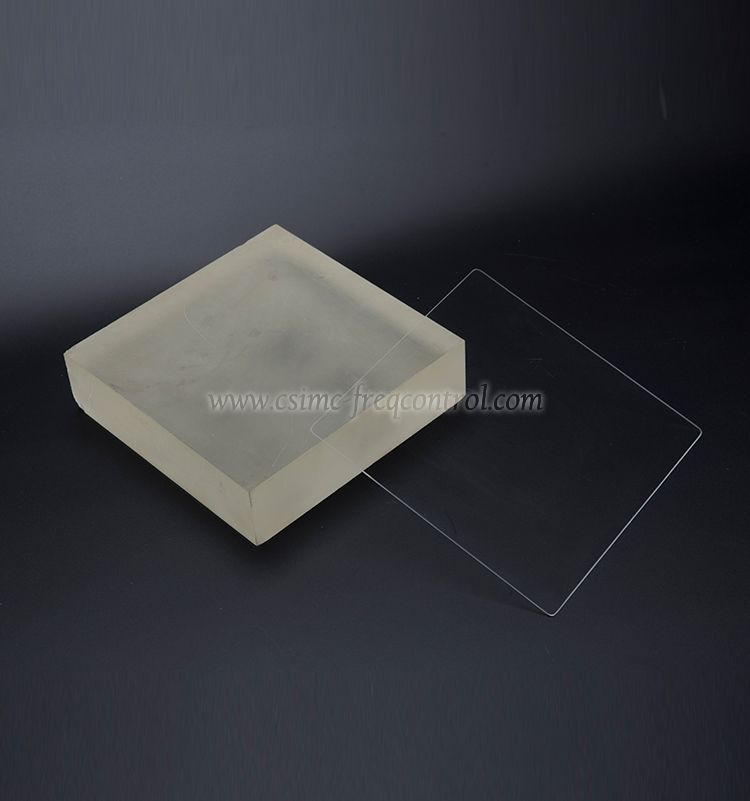

Fused glass wafers have many features that make them attractive for use as carrier wafers in semiconductor manufacturing processes. Fusion is a mature manufacturing process that produces extremely high-quality glass wafers with quite low TTV and low warp.

The wafers are cut from sheets, which makes it straightforward to scale up to 450 mm diameter wafers glass wafers have a CTE that closely matches, of silicon wafers, which can be advantageous in avoiding deformation as the wafer piles are heated and cooled. The optical properties of the material allow for easy inspection techniques to evaluate the quality of the bonds in addition to additional light/laser based processing. Because glass is a fragile material like silicon, it's necessary to carefully manage finishing procedures.

The glass is shaped in thin sheets to a target thickness in the fusion procedure. Therefore It Isn't necessary to grind and polish the surface, thus preventing strength limiting micro-flaws that can stay on the surface. Finally, it had been shown that glass borders can be immensely strong when processed correctly. it is shown properties of glass wafers to similar properties of silicon wafers.

The quality of our China Monitor Crystal is guaranteed and the price is cheap. We also have our own Tellurium Oxide factory. If you are interested in our products, you can contact us.

Copyright © Hangzhou Freqcontrol

Electronic Technology Ltd.

All Rights Reserved | Sitemap |

Powered by